The Three Leaps of Business Transformation

Where Generative AI Fits In

Hey Adopter,

Ever sat through one of those mind-numbing corporate presentations where someone drones on about "digital transformation" while you secretly wonder if they have any idea what they're talking about?

Yeah, me too. 😏

As an industrial engineer from Germany (though I do love living in America now 🇺🇸 🦾),

I'll be using European and, specifically, German examples throughout this newsletter. My background gives me a slightly different perspective on industrial evolution that I think you'll find refreshing.

Three Leaps That Changed Everything (and No, "Synergy" Isn't One of Them)

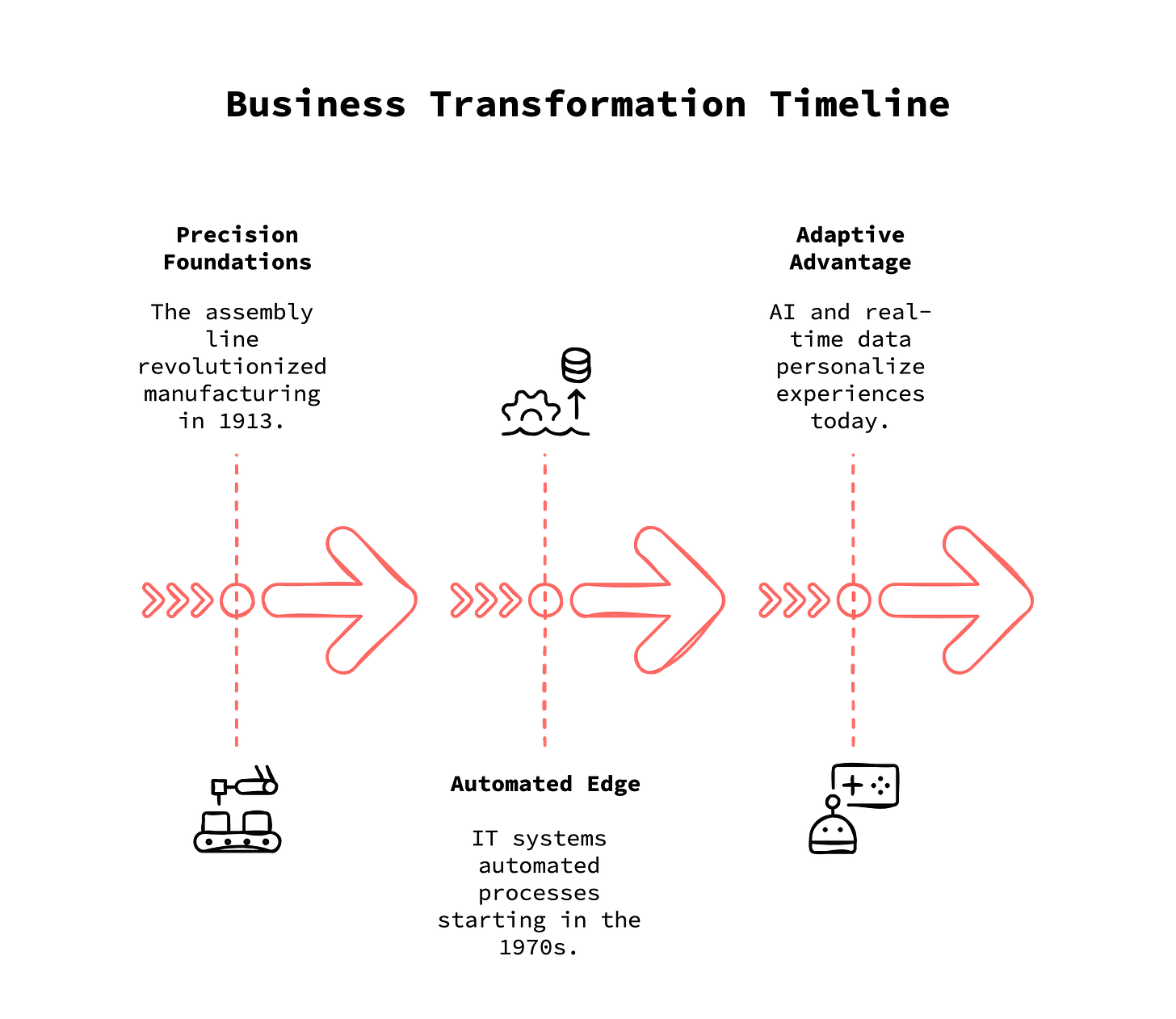

Business transformation has happened in three major leaps. Think of them like software updates, except they took decades instead of interrupting your workday with a "Your computer will restart in 10 minutes" message.

Leap 1: Precision Foundations (1900s-1950s)

When businesses figured out that chaos isn't actually a strategy

Remember Austin Motor Company? Probably not, unless you're a British car enthusiast. But in the 1920s, they were revolutionizing European manufacturing with assembly lines for their Austin Seven. This was the era of standardization—breaking work into measurable, repeatable steps.

While Henry Ford gets most of the credit in America (around 1913), European manufacturers were adapting these principles to their own markets throughout the 1920s-40s. The core innovation was simple but revolutionary: deconstruct complex work into standard, measurable processes.

What it meant for workers then: "Congratulations, you now put on the left door handle. Just the left one. For eight hours. Every day."

Leap 2: Automated Edge (1950s-2000s)

When "I'll get back to you on that" became "the system will process your request"

While American companies like Walmart were automating everything they could get their hands on, European giants like Siemens were quietly revolutionizing industrial automation. Their SIMATIC controllers in the 1950s laid groundwork for what would become the business process re-engineering movement.

The real explosion happened in the 1970s through the 1990s when computing power became accessible enough for widespread business adoption. Siemens' continued innovation in programmable logic controllers throughout the 1970s-80s helped factories automate entire production lines. By the 1990s, enterprise software was digitalizing back-office functions across industries.

What it meant for workers then: "Great news! The computer will now handle those TPS reports. Bad news? You need to learn how to use a computer."

Leap 3: Adaptive Advantage (2010s-Present)

When your business finally started listening instead of just talking

We're here now—the adaptive era. Companies like Bosch aren't just automating; they're creating systems that adapt in real-time. Their AI Center, established in 2017, isn't focused on replacing humans but creating that "missing middle" where humans and AI cooperate.

This leap began taking shape around 2010-2015 as machine learning became practical for business applications. By 2016-2018, companies were implementing predictive analytics at scale. The real transformation started around 2020-2021 with generative AI making what was once science fiction into business reality.

What it means for workers now: "The AI handles the data grunt work while you focus on the judgment calls and creative solutions that actually make us money."

What it means for your career: Massive opportunity if you position yourself as the bridge between AI capabilities and business needs. (Hint: That's exactly what this newsletter helps you do!)

The Big Misconception Everyone Gets Wrong

Despite what dystopian movies suggest, AI systems aren't methodically replacing humans job by job. The research suggests something far more interesting:

AI excels at: Data processing, pattern recognition, repetitive tasks, generating content variations

Humans still dominate at: Resolving ambiguity, creative problem-solving, emotional intelligence, ethical judgment

The most successful companies aren't replacing humans with AI—they're creating powerful human-AI teams. At Bosch, AI handles real-time data analysis while human experts make the final calls on complex decisions.

What This Means For You On Monday Morning

Stop thinking replacement and start thinking augmentation. Where could AI handle the routine parts of your job while you focus on higher-value work?

Consider your "adaptive advantage." How could your team use real-time data to personalize your customer experience?

Be the translator. The most valuable people in organizations today bridge the gap between what AI can do and what the business needs.

Next week, I'll break down exactly how to identify your first AI project for maximum impact (and minimum career risk).

Until then, keep in mind that the robots aren't coming for your job—but the people who know how to work with robots might be.

Adapt & Create,

Kamil