Hershey’s $250M AI bet: margin protection through physics

A 130-year-old company cut product waste by 50% and innovation cycles from five months to five weeks. The approach works for any manufacturer battling tight margins.

Hi Adopter,

Candy making is an art. Just ask the factory operators at Hershey who rejected their company’s IoT initiative four times before finally letting the sensors onto the production floor.

Their scepticism was understandable. These were people who could feel when the Twizzler dough was off. Then some algorithm shows up claiming it can do better?

It could. The system predicts weight drift before it happens, not 15 minutes after when an operator finally checks. That difference is worth $500,000 per year on a single production line.

This is how a brownfield manufacturer built AI into operations without blowing up in the process. (They’ve done that before. More on Halloween 1999 later.)

Download the full case study for the vendor stack, timelines, and measured impact.

50% reduction in product weight variance on instrumented lines

75% reduction in data analysis time after consolidating fragmented data

Five months to five weeks for new product innovation cycles

The lesson hiding in your production floor

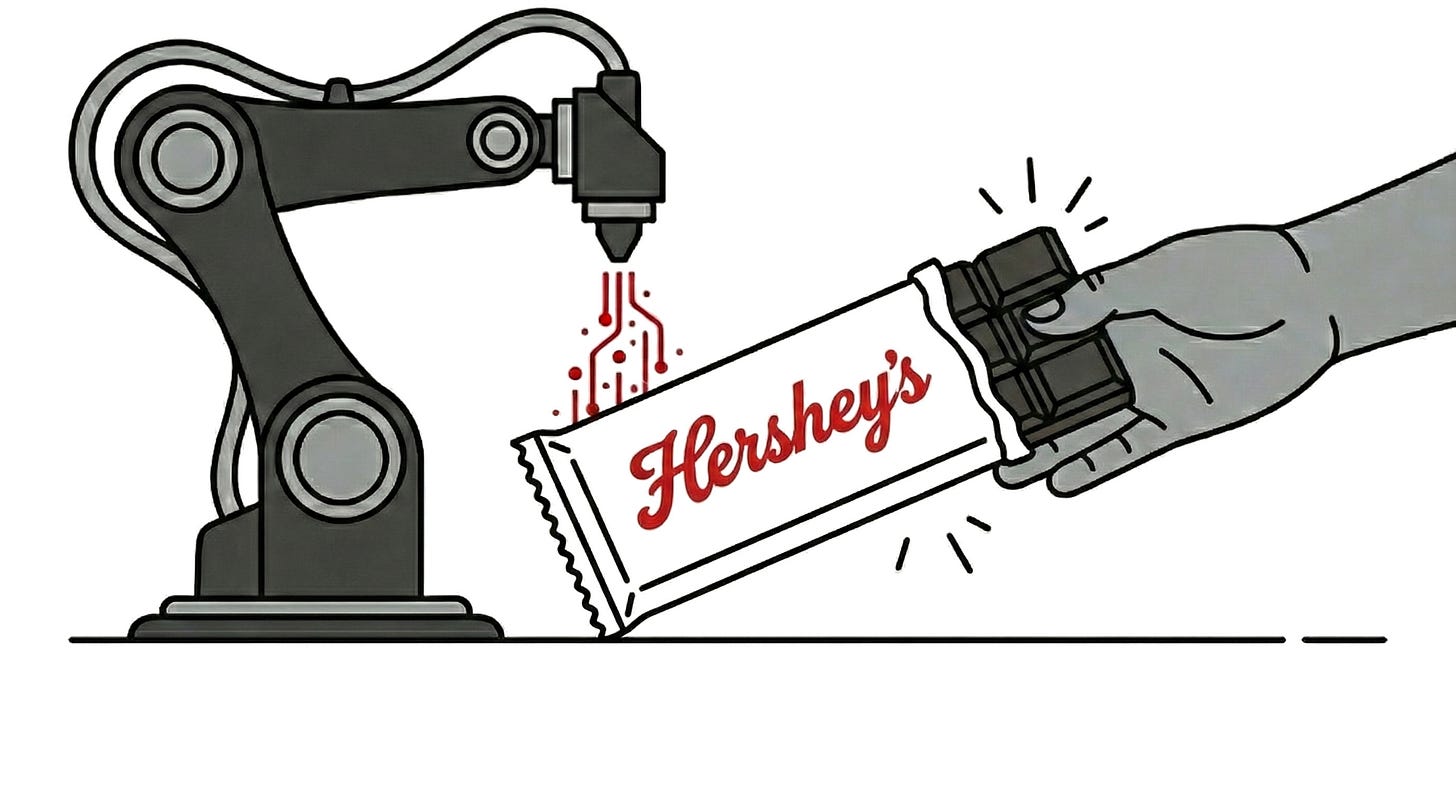

Here’s what most AI strategies get wrong: they start with the technology. Hershey started with the physics.

Every gram of chocolate exceeding the label weight is margin walking out the door. Manufacturers call this “giveaway,” and it’s invisible until you measure it. The fastest AI wins sit where repetition meets variance. Find the process you run thousands of times daily where small inconsistencies compound into real money.